Controlled Atmosphere Stunning with Gentle Induction

Above Ground CAS

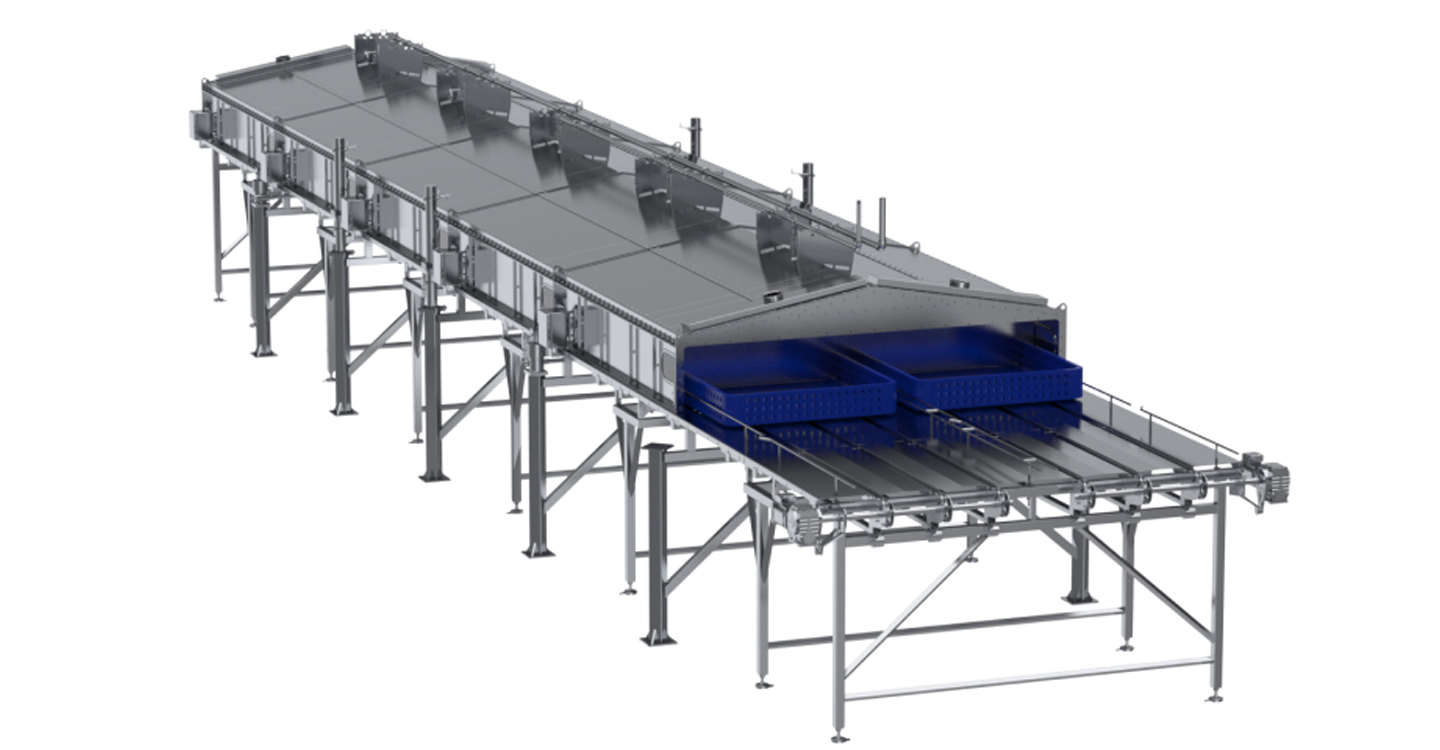

Multiphase CO2 Tunnel Stunning

This dual-lane CAS tunnel is divided internally into five chambers. The birds remain in their drawers throughout the system, and each chamber exposes the birds to an increasing CO2 concentration creating a gentle and controlled stunning process. Stage length and gas concentration levels are adjustable to optimize stunning performance. The modular design of the Above Ground CAS makes it suitable for all capacities.

Benefits

See how UniLoad works

The Drawer

The Module

The Reception System

Gentle Bird Stunning

By adding 02 and clean dry air to the tunnel atmosphere during the induction phase, birds will not perceive the air as unpleasant and will therefore remain calm until they are rendered unconscious.

Observing Animal Welfare during Stunning

In addition to observing the birds through windows on the machine, camera monitoring in each chamber allows animal welfare indicators to be evaluated throughout the stunning process. Real-time monitoring allows for fast corrections.

Easy Maintenance of the Stunning System

A simple hood-lifting design allows the tunnel to be opened and offers quick access to the interior of the machine during cleaning and servicing.

Download our Guide to Best Catching Practices

It offers tips on how to avoid bird injuries during catching and loading.

Control and Monitoring

The stunning process is comfortably controlled from an HMI control panel that offers several information screens regarding the system settings, status and alarm history. Different recipes are available according to bird sizes and the control system monitors the CO2 concentrations based on these recipes.

Safety

The Above Ground CAS System is equipped with a number of safety features concerning both the use of gas and the machinery. Sensors and safety analysers ensure that the CO2 level is always under control.

Heavy Duty Equipment

The drawer conveyor inside the tunnel is a robust, composite transportation chain designed for heavy loads to obtain a high degree of reliability in the reception system.

The Reception System

Configurable to Suit Your Processing

UniLoad is a modular and scalable reception system suitable for all capacities. The size of the UniLoad drawer allows for more birds in each drawer while still protecting animal welfare. Fewer drawers are necessary and conveyors can run at low speed while still feeding a high-speed slaughtering line. Low speed reduces both bird and equipment stress.

Strict Biosecure Measures

UniLoad takes hygiene seriously by focusing on biosecurity in drawer and module design and by providing highly efficient cleaning equipment for the reception system. To avoid cross-contamination between flocks, the bacterial load on the transport equipment is minimized by thorough wash-down after each live bird load.

Soaking the drawers before washing helps the debris to come loose and be removed more easily in the drawer washer

Separate drawer washing for the best cleaning results

Effective module washing before introducing the clean drawers into the modules and picking up a new bird load

See How the Above Ground CAS Works

By adding 02 and clean dry air to the tunnel atmosphere during the induction phase, birds will not perceive the air as unpleasant and will therefore remain calm until they are rendered unconscious.

How Can We Help You?

Tell us about your processing requirements and see how our experts can help you improve your quality, throughput and yield.